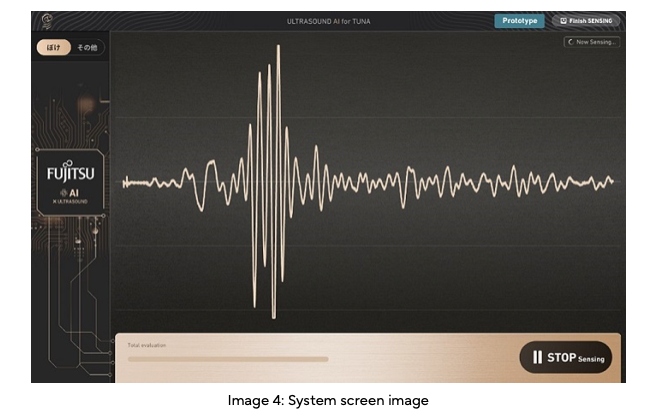

TOKYO, Dec 21, 2022 - (JCN Newswire) - Tokai University and Fujitsu today revealed the successful development of a new technology to inspect the freshness of frozen tuna in Japan. Joint research focused on the development of novel ultrasound AI technology (1), resulting in the world's first technique to measure the meat quality of frozen tuna without the need to cut or damage the product. The new technology thus offers a new method to inspect the quality of frozen tuna without lowering its value, and may one day contribute to greater trust and safety in the global distribution of frozen tuna and other food products.

|

|

|

|

The joint research will be presented by both parties at the Technical Committee Conference of the Society for Ultrasound Research (hosted by the IEICE) to be held in Hiroshima City, Hiroshima Prefecture, Japan, from December 22 to December 23, 2022.

About the joint research

1. Background and challenges

Demand for tuna both in Japan and globally has increased significantly, with 15 countries fishing and producing more than 50,000 tons of tuna in 2020 (2). The recent global Japanese food boom has raised demand for high-quality tuna that is mostly used for sashimi (raw fish).

Most wild-caught, natural tuna is rapidly frozen on board commercial fishing boats, and subsequently delivered via distributers to restaurants and supermarkets to consumers. However, the quality of the tuna largely depends on the conditions at the time of fishing and the way it is handled throughout the distribution process.

Conventional methods for inspection of the freshness and meat quality of frozen tuna usually require inspectors to cut off the tail of the fish to visually examine a cross section of the tuna tail. Cutting the tail of the tuna often damages and ultimately lowers the value of the fish, and the process relies heavily on a limited number of experts trained to accurately conduct quality inspection.

Ultrasound waves are applied in quality testing in a variety of fields as a non-destructive testing method. However, the use for frozen products such as tuna proved to be difficult due to the high attenuation of acoustic waves.

To address these issues, Tokai University under the lead of Professor Keiichi Goto, Department of Fisheries, School of Marine Science and Technology and Fujitsu conducted joint research examining frozen tuna with low-frequency ultrasound waves with low attenuation to inspect the freshness of the fish. By analyzing the waveforms using machine learning (3), the two parties successfully developed the world's first method to determine the freshness of frozen tuna without the need to cut the product.

2. Period of the joint research:

April 1, 2022 to March 31, 2023 (scheduled to continue after FY 2023)

3. Outline of the research:

In order to find the optimum ultrasound frequency to examine frozen tuna, Tokai University and Fujitsu conducted trials at several wave frequencies. Tests showed that ultrasound waves with a relatively low frequency of about 500 kHz delivered optimum results.

To determine possible indicators of insufficient freshness (4), the two parties compared ultrasound waveforms from tuna specimens with good and insufficient freshness quality to examine whether waveforms differed depending on the freshness of the specimens. As a result, Tokai University and Fujitsu discovered that reflection intensity in the middle bone area of tuna specimen with insufficient freshness was especially intense. Based on these findings, the two parties created a machine learning model based on reflected waves from the middle bone of the tuna specimens (5) that is able to correctly inspect the freshness of frozen tuna with an accuracy of 70% to 80% (6).

In addition to waveforms that can be easily differentiated by the human eye (image 2), the newly developed AI technology is also able to identify distinctions in waveforms that are difficult to visually perceive (image 3).

4. Possible use scenarios of the new technology:

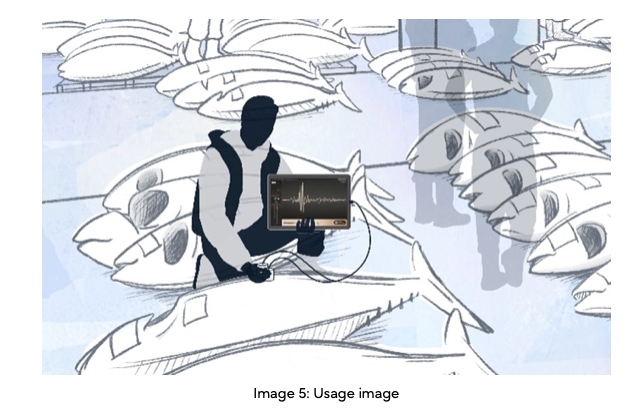

- Wholesalers for marine products can easily inspect the freshness of a whole fish with a handheld device when buying tuna from fishermen

- Applied to inspections at facilities including fishing ports using belt conveyors, the technology could be used for automated batch inspections of the freshness of frozen tuna

5. Future plans:

Moving forward, Tokai University and Fujitsu will conduct trials with additional tuna specimen to increase the accuracy of the newly developed technology and further enhance it to be able to detect other quality defects of frozen tuna including blood clots and tumors.

The two partners further plan to conduct field trials at processing plants for marine products and conduct research to apply the technology to a wide range of areas, including the livestock industry, which handles frozen products, the biological field and the medical field.

(1) Ultrasound AI technology :

A group of AI technologies specialized in processing data acquired by ultrasonography. Ultrasound waves reflected by bones are shown as shadows in data. By reducing or utilizing such characteristics of ultrasound data, Fujitsu is developing AI technology that is robust against issues such as noise peculiar to ultrasound.

(2) 15 countries fishing and producing more than 50,000 tons of tuna in 2020 :

Quoted from "World Tuna Catch and Production Ranking and Transition by Country" (in Japanese)

(3) Machine learning :

A branch of AI. A technique in which an algorithm automatically learns features necessary for object classification from training data. Technology that demonstrates high performance even for complex and fine patterns that are difficult for developers to create.

(4) Insufficient freshness :

A condition in which postmortem rigidity is progressing. In the case of frozen tuna, postmortem rigidity develops between the time it is caught and the time it is frozen, and tunas in the postmortem rigidity state have a lower product value than those frozen immediately after being caught.

(5) Tokai University and Fujitsu cut out reflected waves from the middle bone part and performed machine learning from 222 ultrasound waveforms obtained from 10 tuna slices with good and insufficient quality. In addition to those samples, Tokai University and Fujitsu calculated a freshness score using 126 ultrasound waveforms obtained from a total of 6 tuna slices with good and insufficient quality and verified whether the waveforms from slices with good quality could be distinguished from those with insufficient quality. As a result, Tokai University and Fujitsu discovered a significant difference in the freshness score for specimens with good and insufficient quality.

(6) Tokai University and Fujitsu evaluated the accuracy of the machine learning model using an AUC-ROC (Area Under the Curve of the Receiver Operating Characteristic) Curve. A ROC curve shows the true positive rate on the vertical axis and the false positive rate on the horizontal axis, whereas the area under the curve is obtained between 0.0 and 1.0, and 1.0 is a perfect score value. In general, a certain level of performance can be achieved when the value is higher than 0.7. As a result of evaluating the new technology using AUC-ROC, Tokai University and Fujitsu obtained a value of 0.791, meaning an accuracy of about 70% to 80%.

About Fujitsu

Fujitsu's purpose is to make the world more sustainable by building trust in society through innovation. As the digital transformation partner of choice for customers in over 100 countries, our 124,000 employees work to resolve some of the greatest challenges facing humanity. Our range of services and solutions draw on five key technologies: Computing, Networks, AI, Data & Security, and Converging Technologies, which we bring together to deliver sustainability transformation. Fujitsu Limited (TSE:6702) reported consolidated revenues of 3.6 trillion yen (US$32 billion) for the fiscal year ended March 31, 2022 and remains the top digital services company in Japan by market share. Find out more: www.fujitsu.com.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.com