Over 230 isolator-based filling and closing systems are available in the market, and equipment developers are still engaged in further improvement efforts.

DUBLIN, IRELAND / ACCESSWIRE / December 10, 2024 / "Aseptic Filling Machine Market Industry Trends and Global Forecasts to 2035, by Type of Compatible Primary Container (Vials, Syringes, Cartridges, Ampoules, Capsules, and Other Containers), Scale of Operation, System Throughput, End-user and Key Geographical Regions" report has been added to ResearchAndMarkets.com's offering.

The global aseptic filling machine market is estimated to grow from USD 1.3 billion in the current year to USD 3.4 billion by 2035, at a CAGR of 8.7% during the forecast period to 2035.

Pharmaceutical fill-finish manufacturing is a crucial element of drug production. However, several issues arise in the current drug filling process, including contamination risks, inaccuracies in dose dispensing, and labeling problems. Industry experts estimate that approximately 80% of product recalls stem from packaging-related issues. Additionally, manual interventions in filling lines pose threats to product integrity, as they increase contamination risks due to contact with workers and are often inefficient.

Over the years, pharmaceutical equipment manufacturers have introduced more cost-effective, reliable and efficient machinery, incorporating isolators and restricted access barrier systems (RABS) into their proprietary aseptic fill-finish lines. Many of these systems are intended to minimize human involvement, thereby lowering the risk of operator-related contamination. Moreover, using filling lines where equipment components are individually isolated can lead to substantial cost savings; developers can avoid investing in large, high-end cleanrooms for these filling lines. At present, over 230 isolator-based filling and closing systems are available in the market, and equipment developers are still engaged in further improvement efforts.

As several biologics are currently under development, the opportunity for aseptic fill / finish equipment developers is anticipated to expand further. Moreover, rise in a number of injectable drugs and pipeline candidates is driving the demand for aseptic filling machines.

Aseptic Filling Machine Overview

Key Report Attributes |

Details |

No. of Companies Covered |

45+ |

No. of Isolator based Aseptic Filling Machines Captured |

230+ |

Current Market Size |

USD 1.3 Billion |

Market Size in 2035 |

USD 3.4 Billion |

CAGR |

8.7% |

Type of Primary Container |

|

Scale of Operation |

|

System Throughput |

|

End-user |

|

Key Geographical Regions |

|

ASEPTIC FILLING MACHINE MARKET: KEY INSIGHTS

The report delves into the current state of the aseptic filling machine market and identifies potential growth opportunities within the industry.

Some key findings from the report include:

Presently, over 230 isolator based aseptic filling machines are available in the market; majority of these isolator based aseptic filling machines use vials as compatible primary container.

78% of isolator based aseptic filling systems can perform both filling and closing operations for liquid / powder formulations, followed by the systems capable of performing only filling operations (15%).

The current market landscape of isolator based aseptic filling machines developers is fragmented, featuring the presence of both new entrants and established players; majority of these players are based in Europe.

Leading manufacturers are revolutionizing pharmaceutical production by integrating advanced automation, real-time monitoring, and automated cleaning in aseptic filling systems.

Stakeholders are actively upgrading their existing capabilities to further enhance their respective fill / finish capabilities and comply to the evolving industry benchmarks.

From automation to sustainability, several recent mega trends are shaping the isolator-based aseptic filling machine industry, thereby driving innovation and efficiency in manufacturing processes.

In terms of recent developments, the market had witnessed a substantial partnership activity and a number of conferences related to aseptic pharmaceutical packaging were organized across the globe.

The isolator based aseptic filling machines market is likely to grow at a CAGR of 8.7%, till 2035; presently, majority of the market share is occupied by vials amongst the various compatible primary containers.

The isolator based aseptic filling machines market is anticipated to be primarily driven by the rising need for alternate sterilization methods; Europe is expected to capture larger share (40%) of the market by 2035.

ASEPTIC FILLING MACHINE MARKET: KEY SEGMENTS

Cartridge Segment is the Fastest Growing Segment in the Aseptic Filling Machine Market

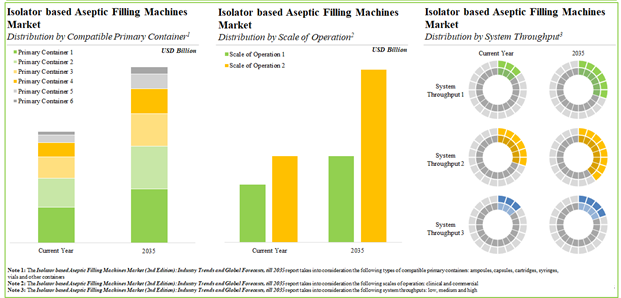

Based on type of primary containers, the market is segmented into vials, syringes, cartridges, ampoules, capsules, and other containers. It is worth highlighting that the majority of current aseptic filling machine market is captured by pharmaceutical vials. This trend is likely to remain the same in the coming decade. It is worth mentioning that vials offer various advantages, such as the ability to pre-sterilize the containers through various terminal sterilization techniques and minimal risk of breakage during handling and transportation and ease of filling as compared to other primary packaging containers.

By Scale of Operation, Commercial Scale is Likely to Dominate the Aseptic Filling Machine Market During the Forecast Period

Based on scales of operation, the market is segmented into clinical and commercial scale. It is worth highlighting that revenues generated from isolator based aseptic filling machines operating at commercial scale will be the primary driver of the overall market.

High System Throughputs is Expected to Capture the Highest Share in the Aseptic Filling Machine Market During the Forecast Period

Based on type of system throughput, the market is segmented into low, medium and high system throughputs. At present, the largest market share is captured by high throughput aseptic filling machines. This can be attributed to the fact that both in-house manufacturers and contract manufacturing organizations will use the high throughput isolator based filling machines for commercial scale manufacturing.

Currently, the Pharma / Biotech Companies Hold the Maximum Share of the Aseptic Filling Machines Market

Based on the end-users, the market is segmented into pharma / biotech companies and contract service providers. It is worth highlighting that, currently, pharma / biotech companies hold the largest share of isolator based aseptic filling machines market.

Europe Accounts for the Largest Share of the Market

Based on key geographical regions, the market is segmented into North America, Europe, Asia-Pacific and Rest of the World. At present, Europe captures the maximum share of the market opportunity, and this trend is unlikely to change in the coming years. It is worth highlighting that over the years, the market in Asia-Pacific and Rest of the World is expected to grow at a higher CAGR.

Key Players in the Aseptic Filling Machine Market include:

AST

Bausch+Strobel

Dara Pharma

Groninger

IMA Group

Marchesini

OPTIMA

Syntegon

Tofflon

ASEPTIC FILLING MACHINE MARKET: RESEARCH COVERAGE

The report features an in-depth analysis of the aseptic filling machine market, focusing on key market segments, including type of compatible primary container, scale of operation, system throughput, end-user and key geographical regions.

The report analyzes various factors such as drivers, restraints, opportunities, and challenges affecting the market growth.

A comprehensive evaluation of isolator based aseptic filling systems, considering various parameters, type of system, maximum system throughput, type of compatible primary container, type of formulation. It also provides an assessment of the companies involved in the development of isolator based aseptic filling systems based on their year of establishment, company size, location of headquarters and leading players.

A comprehensive competitive analysis of isolator based aseptic filling systems, examining factors such as scale of operation, system throughput, compatible primary containers, type of formulation and other important product related specifications.

In-depth profiles of key players in aseptic filling machines market, focusing on company overviews, proprietary products, recent developments and an informed future outlook.

A discussion on general regulatory guidelines for aseptic processing, and specific recommendations related to isolator and blow-fill-seal technologies used in the aseptic fill / finish process.

An analysis of recent trends, covering partnerships and collaborations, and conferences held in this domain.

KEY QUESTIONS ANSWERED IN THIS REPORT

How many companies are currently engaged in this market?

Which are the leading companies in this market?

What is the current and future market size?

What is the CAGR of this market?

How is the current and future market opportunity likely to be distributed across key market segments?

REASONS TO BUY THIS REPORT

The report provides a comprehensive market analysis, offering detailed revenue projections of the overall market and its specific sub-segments. This information is valuable to both established market leaders and emerging entrants.

Stakeholders can leverage the report to gain a deeper understanding of the competitive dynamics within the market. By analyzing the competitive landscape, businesses can make informed decisions to optimize their market positioning and develop effective go-to-market strategies.

The report offers stakeholders a comprehensive overview of the market, including key drivers, barriers, opportunities, and challenges. This information empowers stakeholders to stay abreast of market trends and make data-driven decisions to capitalize on growth prospects.

ADDITIONAL BENEFITS

Complimentary PPT Insights Packs

Complimentary Excel Data Packs for all Analytical Modules in the Report

10% Free Content Customization

Detailed Report Walkthrough Session with Research Team

Free Updated report if the report is 6-12 months old or older

Key Topics Covered:

INTRODUCTION

Overview of Drug Fill / Finish Processes

Traditional Methods of Fill / Finish

Aseptic Fill / Finish Technique

Need for Aseptic Fill / Finish Techniques

-

Advanced Aseptic Fill / Finish Processes: Blow-Fill-Seal Aseptic Technology

Isolator Systems

Restricted Access Barrier Systems (RABS)

Comparison between Isolator Systems and RABS

Advantages of Advanced Aseptic Fill / Finish Techniques

Regulatory Guidelines for Aseptic Fill / Finish

Future Perspectives

ISOLATOR BASED ASEPTIC FILLING SYSTEMS: OVERALL MARKET LANDSCAPE

Isolator based Aseptic Filling Systems: Overall Market Landscape

Isolator based Aseptic Filling Systems: Developer Landscape

ISOLATOR BASED ASEPTIC FILLING AND CLOSING SYSTEMS: PRODUCT COMPETITIVENESS ANALYSIS

Product Competitiveness Analysis: Peer Group I

Product Competitiveness Analysis: Peer Group II

Product Competitiveness Analysis: Peer Group III

COMPANY PROFILES

AST

Bausch+Strobel

Dara Pharma

Groninger

IMA Group

Marchesini Group

OPTIMA

Syntegon

Tofflon

RECENT DEVELOPMENTS

Partnership Models

-

Isolator based Aseptic Filling Systems Market: Partnership Activity

List of Partnerships and Collaborations

Isolator based Aseptic Filling Systems Market: Recent Conferences

REGULATORY GUIDELINES: ASEPTIC PROCESSING

Overview of Cleanroom Grades

-

General Guidelines for Aseptic Processing

Requirements for Buildings and Facilities

Requirements for Personnel Training, Qualification and Monitoring

Requirements for Components and Containers / Closures

Guidelines for Using Isolator Technology

Guidelines for Using Blow / Fill / Seal Technology

MARKET FORECAST AND OPPORTUNITY ANALYSIS

Global Isolator based Aseptic Filling Systems Market: Historical Trends (Since 2019) and Forecasted Estimates (to 2035)

Isolator based Aseptic Filling Systems Market: Distribution by Scale of Operation, 2019, Current Year and 2035

Global Isolator based Aseptic Filling Systems Market: Distribution by Type of Compatible Primary Container, 2019, Current Year and 2035

Global Isolator based Aseptic Filling Systems Market: Distribution by System Throughput, 2019, Current Year and 2035

Global Isolator based Aseptic Filling Systems Market: Distribution by End-user, 2019, Current Year and 2035

Isolator based Aseptic Filling Systems Market: Distribution by Key Geographical Regions, 2019, Current Year and 2035

For more information about this report visit https://www.researchandmarkets.com/r/3xjm3h

About ResearchAndMarkets.com

ResearchAndMarkets.com is the world's leading source for international market research reports and market data. We provide you with the latest data on international and regional markets, key industries, the top companies, new products and the latest trends.

Contact Data

CONTACT: ResearchAndMarkets.com

Laura Wood, Senior Press Manager

press@researchandmarkets.com

For E.S.T Office Hours Call 1-917-300-0470

For U.S./ CAN Toll Free Call 1-800-526-8630

For GMT Office Hours Call +353-1-416-8900

Source: Research and Markets

View the original press release on accesswire.com