Choosing the Right Skid Steer Loader Tracks

Selecting the right skid loader tracks ensures your equipment performs efficiently across various tasks. By understanding key factors like tread patterns, track width, and terrain compatibility, you can make informed decisions that enhance your machine’s capabilities.

Tread Patterns

Tread patterns play a crucial role in determining how well your skid loader operates on different surfaces. Choosing the right pattern depends on the type of terrain and the specific application.

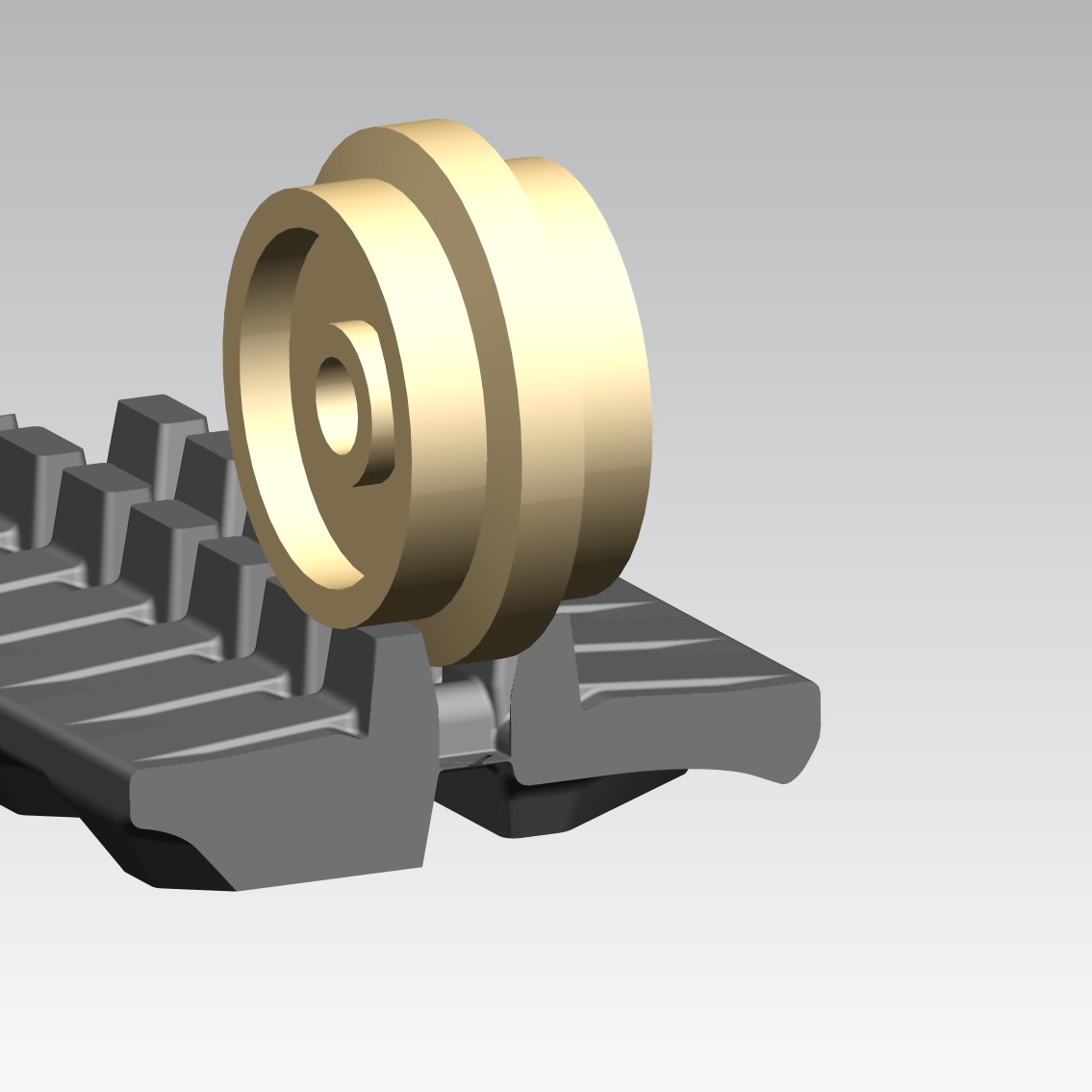

- The off-set excavator tracks pattern, like the one featured in the T450X100K, provides excellent traction and stability. This design works well for demanding environments, ensuring smooth operation and reduced slippage.

- Multi-purpose treads offer versatility. These patterns adapt to a variety of surfaces, making them ideal for users who frequently switch between different terrains.

By selecting the appropriate tread pattern, you can optimize your skid loader’s performance and ensure consistent results.

Track Width

Track width significantly impacts how your skid loader handles different ground conditions. Understanding the benefits of wider and narrower tracks helps you choose the best option for your needs.

- Wider tracks distribute the machine’s weight over a larger area. This feature improves flotation on soft ground, such as sand or mud, reducing the risk of sinking or getting stuck.

- Narrower tracks enhance maneuverability. They allow your skid loader to navigate tight spaces with ease, making them suitable for urban or confined work areas.

Choosing the correct track width ensures your equipment remains efficient and adaptable to the task at hand.

Terrain Compatibility

Matching your skid loader tracks to the operating environment is essential for achieving optimal performance. Tracks designed for specific terrains provide better results and reduce wear.

- Evaluate the terrain where you will use your skid loader. For example, tracks like the T450X100K excel in both rugged and smooth environments, offering reliable performance.

- Consult manufacturer recommendations to ensure compatibility. Gator Track provides detailed guidelines to help you select tracks that meet your requirements.

By aligning track specifications with your working conditions, you maximize efficiency and protect your equipment from unnecessary strain.

Rubber tracks, such as the Rubber Track T450X100K by Gator Track, transform how your skid loader performs. They enhance traction, stability, and adaptability, allowing you to handle diverse tasks with ease. By addressing durability and wear, you ensure long-term efficiency and reduce operational costs. Regular maintenance keeps your equipment in top condition, while selecting the right skid loader tracks maximizes performance. These steps not only extend the lifespan of your machine but also improve its reliability. Investing in high-quality tracks ensures your skid loader operates at its best for years to come.

FAQ

What are the main advantages of using rubber tracks over traditional tires?

Rubber tracks provide better traction, stability, and adaptability compared to traditional tires. They distribute weight evenly, reducing ground pressure and minimizing damage to sensitive surfaces. Rubber tracks also perform well on various terrains, including mud, sand, and snow, making them a versatile choice for skid loaders.

How do rubber tracks improve traction on challenging surfaces?

Rubber tracks enhance traction by increasing the contact area between the machine and the ground. This design ensures a firm grip on loose or uneven surfaces like gravel or wet soil. The off-set excavator track pattern, such as the one in the T450X100K, further boosts stability and reduces slippage.

Are rubber tracks suitable for all types of terrains?

Yes, rubber tracks are highly adaptable and work efficiently on diverse terrains. Whether you operate on rugged landscapes, soft ground, or paved surfaces, rubber tracks maintain consistent performance. Their versatility makes them ideal for tasks in construction, landscaping, and agriculture.

How often should I inspect my rubber tracks?

You should inspect your rubber tracks regularly, ideally before and after each use. Look for signs of wear, such as cracks, cuts, or uneven treads. Frequent inspections help you identify potential issues early, preventing costly repairs and ensuring optimal performance.

What is the lifespan of rubber tracks?

The lifespan of rubber tracks depends on factors like usage, maintenance, and operating conditions. High-quality tracks, such as the T450X100K, are built with tear-resistant materials and steel cores, offering extended durability. Proper care and routine maintenance can significantly increase their longevity.

How do I clean my rubber tracks effectively?

To clean your rubber tracks, remove debris and mud after each use. Use a pressure washer or appropriate cleaning tools to reach lodged dirt. Focus on areas where stones or other materials may accumulate. Keeping your tracks clean prevents unnecessary wear and ensures smooth operation.

Can I use rubber tracks in wet or muddy conditions?

Yes, rubber tracks perform exceptionally well in wet or muddy conditions. Their design reduces slippage and provides better control, allowing you to work efficiently even in challenging environments. This makes them a reliable choice for tasks in unpredictable weather or terrain.

What factors should I consider when choosing rubber tracks?

When selecting rubber tracks, consider factors like tread patterns, track width, and terrain compatibility. For example, the T450X100K features an off-set excavator track pattern for excellent traction. Wider tracks improve flotation on soft ground, while narrower tracks enhance maneuverability in tight spaces.

How do I store rubber tracks to maintain their quality?

Store your rubber tracks in a cool, dry place away from direct sunlight and chemicals. Clean them thoroughly before storage to remove debris and mud. Proper storage practices prevent degradation and ensure your tracks remain durable and ready for use.

Why should I invest in high-quality rubber tracks like the T450X100K?

High-quality rubber tracks, such as the T450X100K, offer superior durability, traction, and adaptability. They reduce wear and tear, minimize downtime, and enhance your skid loader’s performance. Investing in premium tracks ensures long-term efficiency and cost savings for your equipment.

Media Contact

Company Name: Gator Track Co., Ltd.

Email: Send Email

Country: China

Website: https://www.gatortrack.com/